Dental implant treatment is a widely adopted solution for replacing missing teeth. The components used throughout the process are continuously evolving to accommodate a broad range of clinical situations and patient needs. Among them, the dental implant abutment plays a particularly crucial role, serving as the connector between the implant post and the final prosthetic restoration.

To ensure long-term success, the abutment must exhibit high mechanical strength, excellent biocompatibility, and strong resistance to corrosion. These properties are essential in providing a durable, stable, and lasting restoration for the patient in the challenging environment of the oral cavity.

The dental implant abutment serves as the critical connector between the titanium implant fixture and the prosthetic crown or restoration. It plays a pivotal role in the implant procedure by providing a stable and secure foundation for the artificial tooth. Given its position, the abutment must exhibit long-term durability, high mechanical stability, and excellent biocompatibility to minimise the risk of inflammation or rejection.

Additionally, the abutment material must possess strong corrosion resistance to withstand the challenging biological and chemical environment of the oral cavity, thereby ensuring the longevity and functional integrity of the implant restoration.

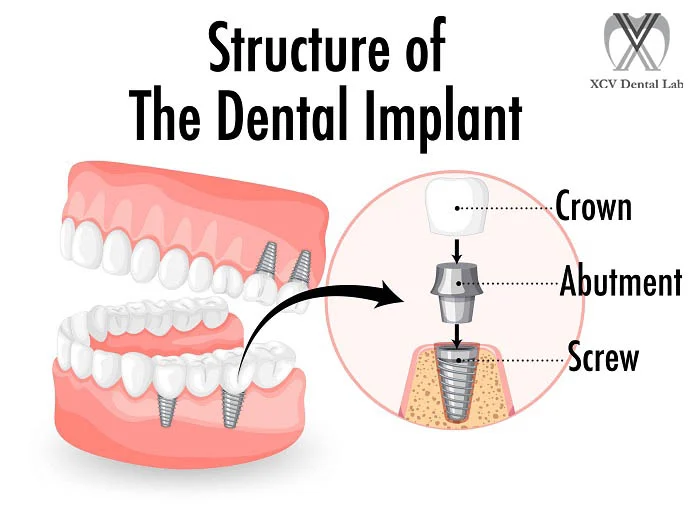

A dental implant abutment is a vital component in the overall implant system. In terms of position, the abutment sits between the implant fixture, which is a titanium post surgically placed in the jawbone, and the visible prosthetic restoration, such as a crown, bridge, or denture. It acts as a connector, firmly joining the implant beneath the gum line to the artificial tooth above, ensuring stability, alignment, and long-term function.

Structurally, abutments are often cylindrical or conical in shape, with a lower portion designed to screw securely into the implant, and an upper portion shaped to support the final restoration. Abutments may vary in height, angulation, and finish line design depending on clinical requirements and the specific position in the mouth.

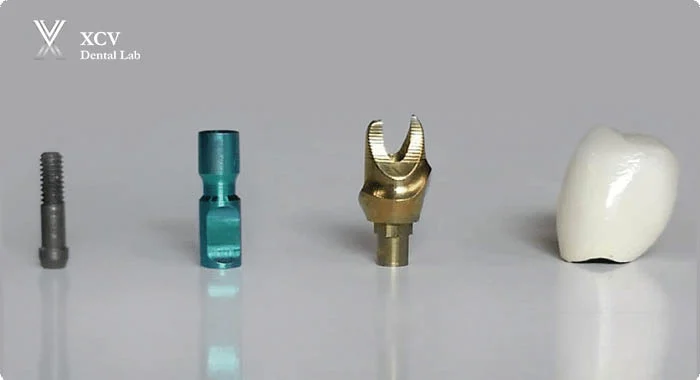

Common materials used in abutment fabrication include titanium, zirconia, and occasionally precious metal alloys like gold. Titanium remains the most commonly used material due to its strength, lightweight nature, and excellent biocompatibility. Zirconia abutments, on the other hand, are often selected in anterior regions where aesthetics are paramount, thanks to their tooth-like colour and natural translucency. In some specialised cases, gold or customised alloy abutments may be chosen for precise fit and optimal tissue response.

Selecting the appropriate abutment is essential for achieving a durable, functional, and aesthetic outcome in implant dentistry.

Dental implant abutments come in a variety of types, each designed to suit different clinical situations and patient needs. The three main types include stock abutments, custom abutments, and angled abutments.

Stock abutments, also known as prefabricated abutments, are mass-produced in standard shapes and sizes. They are typically made from titanium and are available for immediate use, making them a cost-effective and time-efficient option. While suitable for straightforward cases—particularly in the back teeth—they may not provide an ideal fit or gum contour in more aesthetically demanding areas.

Custom abutments, on the other hand, are individually designed using digital scans or physical impressions of the patient’s mouth. This allows for precise control over the angulation, height, and margin position of the abutment, leading to better soft tissue support, improved aesthetics, and a more natural emergence profile. They can be made from titanium for strength or zirconia for high aesthetics, especially in the anterior region.

Angled abutments are designed for implants that are placed at a tilt, often due to limited bone or anatomical restrictions. These abutments are pre-angled (commonly 15° or 25°) to help align the final restoration in a functional and visually pleasing way, without requiring surgical repositioning of the implant.

Placing the abutment is a critical step that follows the complete osseointegration of the implant fixture within the jawbone. This procedure typically takes place around 3 to 6 months after implant placement, depending on the implant site and the patient’s healing rate. After clinical and radiographic evaluation, the clinician will expose the implant if necessary, remove the healing abutment (if one has been placed), and proceed to seat the definitive abutment.

The abutment should be selected based on appropriate height, angulation, and finish line design to provide optimal soft tissue support, promote a natural gingival contour, and offer a stable foundation for the final restoration. In cases where a custom abutment is indicated, the workflow generally includes intraoral scanning and CAD/CAM design to achieve maximum precision and aesthetic integration.

Once the abutment is placed, it must be torqued to the manufacturer’s recommended value to ensure mechanical stability and prevent complications such as screw loosening or micro-movement. Additionally, the fit of the abutment should be carefully assessed for accuracy and proper adaptation to surrounding soft tissues. Patient comfort must also be confirmed prior to taking the final impression or digital scan for the definitive prosthesis.

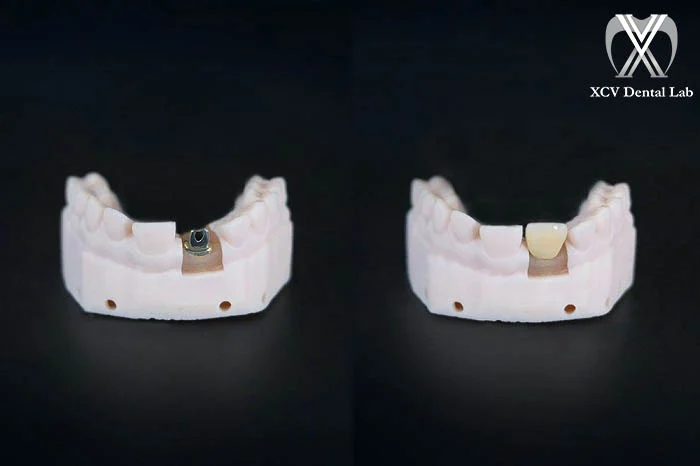

For clinicians seeking a smooth and efficient delivery appointment for cement-retained implant restorations, custom abutments offer a precise and predictable solution. At XCV, our custom abutments are expertly milled using advanced CAD/CAM technology to create a natural-looking emergence profile that optimises soft tissue contours and enhances the aesthetic outcome of the final crown.

Thanks to their mechanical strength, custom titanium abutments are commonly used in all regions of the mouth, including posterior sites where occlusal forces are highest. For cases demanding superior aesthetics—particularly in the anterior region—zirconia abutments with titanium bases are a preferred choice, offering excellent translucency and a tooth-like appearance.

XCV custom abutments are compatible with most major implant systems and are individually designed to follow each patient’s unique gingival anatomy, ensuring a precise and comfortable fit. With dedicated dental CAD software, crown margins can be positioned at or just below the gingival surface, making excess cement easier to remove and improving long-term peri-implant tissue health.