At XCV Dental Lab, innovation is not just a goal—it’s a commitment. That’s why we’re proud to announce the latest addition to our state-of-the-art digital production center: the CORiTEC 350i PRO+ milling machine by imes-icore. This advanced piece of technology is revolutionizing how we fabricate restorations, giving our dental partners faster turnaround times, greater precision, and superior results across all restorative categories.

The CORiTEC 350i PRO+ is a next-generation 5-axis CNC milling machine designed specifically for high-end dental applications. Engineered for power, speed, and versatility, it supports both wet and dry milling, making it ideal for processing a wide range of materials—from zirconia and PMMA to glass ceramics, hybrid composites, and even titanium and CoCr.

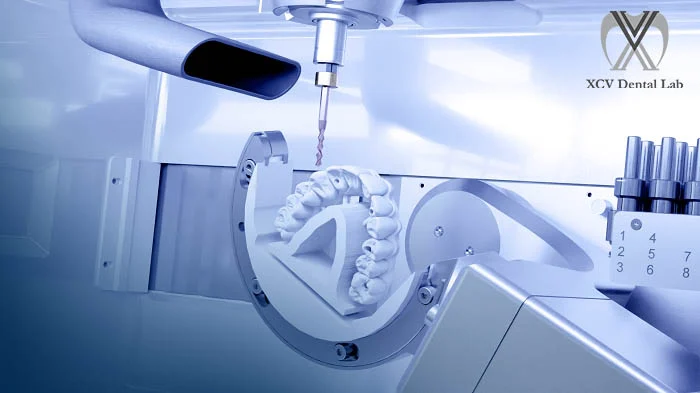

CORiTEC 350i PRO+ with 5-axis simultaneous machining for high-precision dental restorations

With simultaneous 5-axis machining and high-resolution servo motors, the 350i PRO+ produces restorations with incredibly fine detail and ultra-smooth surfaces. This means:

Our new milling system enables us to mill:

This level of versatility allows us to meet virtually any clinical need with greater efficiency.

Milling zirconia, PMMA, and titanium effortlessly with CORiTEC 350i PRO+ advanced spindle system

With the enhanced automation, tool-changing systems, and intelligent job scheduling capabilities of the 350i PRO+, we can complete more cases in less time. Whether you need a full-arch zirconia restoration or a single-unit crown, our production process is now faster and more scalable than ever.

Digitally controlled from start to finish, restorations milled on the CORiTEC 350i PRO+ are consistent, repeatable, and accurate, eliminating variability and reducing remakes.

Close-up of 350i PRO+ dry and wet milling chamber for versatile dental production workflows

For clinicians, this investment translates to:

And with our immaculate communication and technical support, XCV Dental Lab is your trusted partner throughout every stage of the restorative process.

350i PRO+ integrated with smart control software for fully automated, precise milling

The addition of the CORiTEC 350i PRO+ further enhances our digital capabilities and reflects our ongoing commitment to delivering exceptional quality through innovation. At XCV Dental Lab, we don’t just follow technology trends—we lead them, so you can deliver outstanding care with confidence.

Send us your next digital or conventional case and see how our new milling technology can elevate your restorative outcomes.