Titanium frameworks have become a gold standard in implant-supported prosthetics due to their exceptional biocompatibility, strength, and lightweight properties. But not all titanium frameworks are created the same. At XCV Dental Lab, we offer both 3D printed titanium and milled titanium frameworks, and each has distinct advantages.

Understanding the difference between these two fabrication methods is key to selecting the right solution for your patients and your clinical workflow.

1. Fabrication Process

Milled Titanium Frameworks

- Created from a solid block of titanium using subtractive manufacturing.

- CNC machines remove material to carve out the final framework.

- Highly accurate and ideal for full-arch restorations requiring rigidity and passive fit.

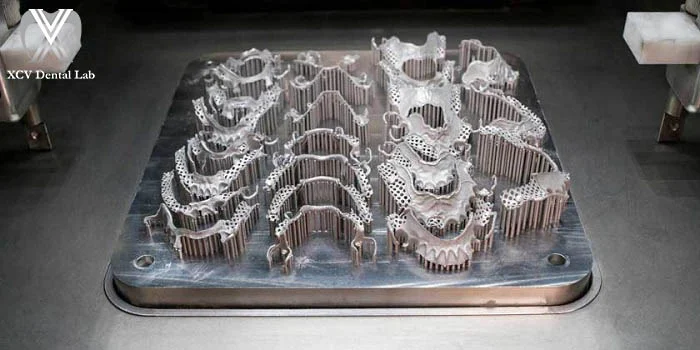

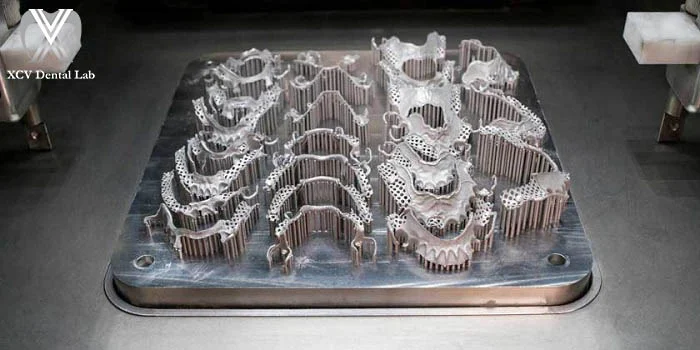

3D-Printed Titanium Frameworks

- Built layer-by-layer using Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS).

- Enables complex geometries and thinner structures that are not possible with milling.

- Less material waste and often more efficient for partial designs.

2. Precision & Fit

- Milled Frameworks:

Offer unmatched accuracy and passive fit, especially in full-arch implant cases where marginal tolerances are critical. - Printed Frameworks:

Still highly accurate, but may require more post-processing. Modern printers have minimized the gap, making printed frameworks viable for most applications, especially when optimized by experienced labs.

3. Design Flexibility

- Printed Titanium:

Enables lighter, more flexible designs, like intricate mesh structures or delicate support bars—ideal for overdentures or hybrid frameworks with space constraints. - Milled Titanium:

More rigid and bulkier due to milling tool limitations. Best for solid, strong base designs, but not ideal for very thin or perforated structures.

4. Strength and Durability

Both methods use Grade 5 titanium (Ti-6Al-4V), offering excellent long-term performance.

- Milled Frameworks:

Tend to be denser and may offer marginally better mechanical properties due to their solid, uniform structure. - Printed Frameworks:

Strong enough for most applications, but their internal microstructure may vary slightly due to the layer-by-layer fabrication. Post-processing (heat treatment and surface finishing) helps equalize performance.

5. Turnaround Time and Cost

- Printed Titanium:

Typically faster and more material-efficient. Cost-effective for partials, hybrid designs, or multiple-unit cases. - Milled Titanium:

Longer machine time and more material usage = higher cost. Best reserved for premium full-arch or bar-supported cases.

When to Use Each at XCV Dental Lab

| Use Case | Best Option |

| Full-arch implant bridge | Milled Titanium |

| Thin bar-supported overdentures | Printed Titanium |

| Complex partial designs | Printed Titanium |

| Passive-fit critical cases | Milled Titanium |

| Cost-sensitive or fast turnaround | Printed Titanium |

Why It Matters to Your Patients

Choosing the right framework type ensures:

- Better comfort

- Improved esthetics

- Long-lasting performance

- Fewer adjustments and remakes

At XCV Dental Lab, we’ll guide you toward the best choice based on the clinical requirements, restoration type, and your preferences.

Let’s help you achieve precision, strength, and satisfaction in every implant case.

Email: info@xcvdental.com.au

Phone: (02) 9055 7747