At XCV Dental Lab, we specialize in All-on-X restorations—full-arch implant solutions that restore both form and function for edentulous patients. But what actually happens behind the scenes? Let’s take a closer look at the All-on-X process from a dental lab’s perspective and how we turn digital plans into life-changing smiles.

All-on-X is a full-arch, fixed implant restoration supported by four or more implants (hence the “X”). It’s ideal for patients who are fully edentulous or soon-to-be, offering a stable, aesthetic, and permanent solution—often in a single day.

We’ve fine-tuned our lab process to ensure precision, predictability, and seamless collaboration with clinicians. Here’s how it works:

Everything begins with digital planning. Once we receive your intraoral scans, CBCT, photos, and bite data, our team loads them into advanced software like Exoplan or Blue Sky Plan.

We collaborate with the surgical team to:

Outcome: A shared, data-driven plan for a predictable result.

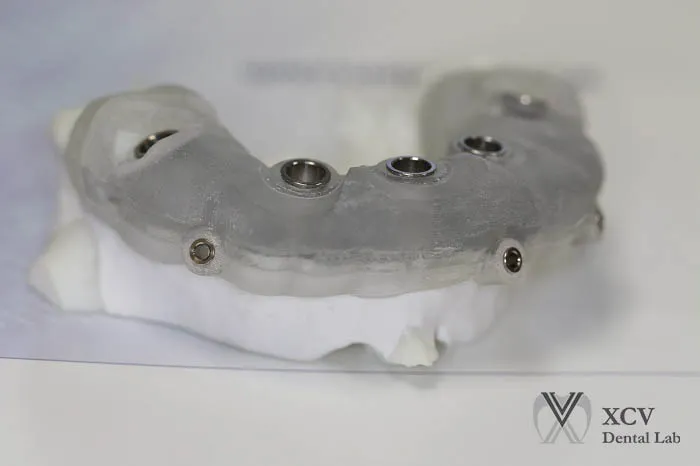

Using the approved implant plan, we design a custom surgical guide to aid in precise implant placement. Our guides are 3D printed in-house using biocompatible, high-precision resin.

Outcome: Faster surgery, accurate implant placement, reduced risk.

For same-day smiles, we pre-fabricate a conversion prosthesis—a temporary denture converted chairside post-surgery to attach to the implants.

Outcome: Patients leave surgery with a secure, functional smile.

After the healing phase, we move on to creating the final restoration. Our lab uses CAD/CAM technology to design a prosthesis that is both durable and lifelike.

Materials commonly used:

Outcome: Long-lasting, high-function, aesthetic result personalized to each patient.

Every final case goes through comprehensive QC:

Once it passes inspection, your case is delivered ready for insertion, on time and stress-free.

Outcome: Confident delivery with fewer chairside adjustments.

At XCV Dental Lab, we combine technology, artistry, and surgical coordination to deliver predictable, beautiful All-on-X cases. Whether it’s digital planning, immediate load prosthetics, or full-contour zirconia arches—we’re with you every step of the way.