In the ever-evolving field of dental technology, 3D–printed chrome frameworks are redefining how we approach removable prosthetics. At XCV Dental Lab, we’re proud to offer this advanced solution, combining traditional strength with digital precision to deliver better results for patients and practitioners alike.

Traditionally, cobalt-chrome (Co-Cr) frameworks for partial dentures were fabricated using wax-ups and lost-wax casting techniques. While effective, these processes are time-consuming, technique-sensitive, and can introduce inconsistencies.

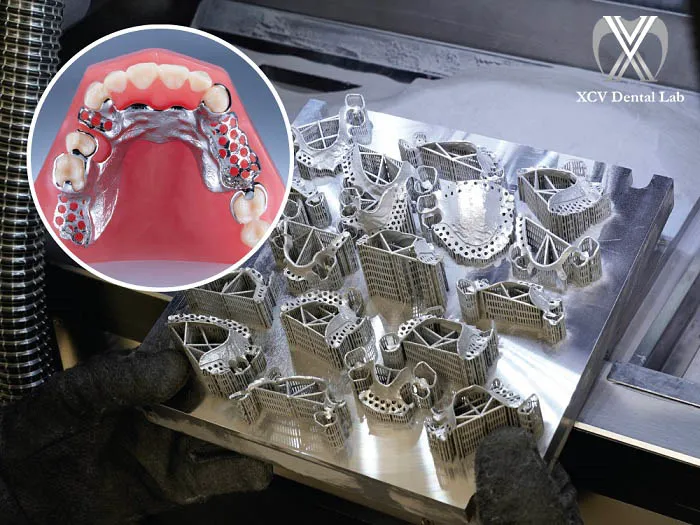

3D printed chrome frameworks, however, are created using Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS)—advanced additive manufacturing methods that fuse metal powder layer-by-layer to form a high-precision, digitally designed framework.

Digital design ensures a better fit, fewer chairside adjustments, and improved comfort for patients. Precision tolerances lead to more predictable seating.

With CAD software, we can design more refined structures, optimize clasp positioning, and improve aesthetic outcomes, especially in cases with complex anatomy.

Unlike traditional casting, which can vary based on technician skill and materials, 3D printing produces repeatable, high-quality outcomes every time.

The digital workflow shortens production timelines. Files can be transmitted instantly, frameworks printed overnight, and delivered faster.

SLM-produced chrome cobalt frameworks are strong yet lightweight, offering long-term durability without compromising on patient comfort.

3D printed chrome frameworks are ideal for:

At XCV Dental Lab, we blend the artistry of prosthetics with the efficiency of digital dentistry. Our 3D-printed chrome frameworks are created with clinical performance in mind, so you can deliver superior prosthetics with fewer remakes and happier patients.

Upgrade your removable prosthetic workflow today.

Email: info@xcvdental.com.au

Phone: (02) 9055 7747